- #ARTEC STUDIO MIRROR OBJECTS MANUAL#

- #ARTEC STUDIO MIRROR OBJECTS PRO#

- #ARTEC STUDIO MIRROR OBJECTS SOFTWARE#

We decided not to wash it beforehand we needed a matte surface anyway, so the additional presence of some road dust was in our favor. The car was delivered to the shop and we set about giving its bodywork a light dusting. The Eva scanner has its own target illumination system that evens out lighting inconsistencies, and the sunlight that day wasn’t bright enough to compete with it.

Nonetheless, we could just as easily have done this scan outdoors. Scanning in daylight isn’t the best option, since excessive or inconsistent brightness can interfere with the process. We carried out the scan indoors at a repair shop. The appearance of 3D scanners brought the digital revolution to the industry.

#ARTEC STUDIO MIRROR OBJECTS MANUAL#

Everything was done “by eye” using manual measurements and physical casts of actual parts, which didn’t contribute much to quality. Photogrammetry wasn’t used in automotive tuning and repair for the simple reason that it was too expensive and labor-intensive.

#ARTEC STUDIO MIRROR OBJECTS SOFTWARE#

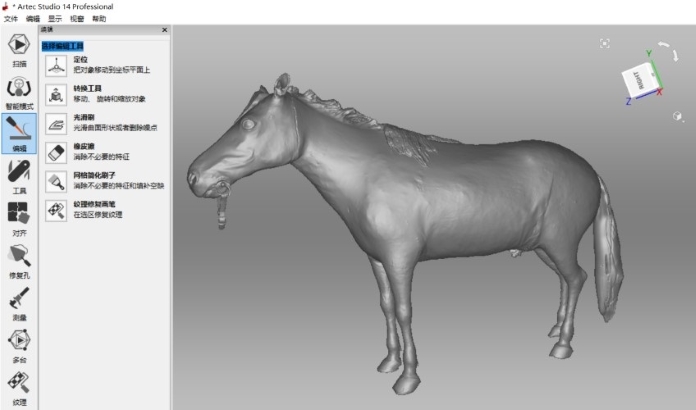

How digital 3D models used to be madeīefore the advent of 3D scanners, digital models of three-dimensional objects were created manually in CAD software using blueprints, measurements and photographs as references. Incidentally, we stock a wide range of 3D scanners at Top 3D Shop and we’ll be happy to help you choose one that fits your needs.Ī digital model generated from the 3D scan. With a tripod-mounted scanner the whole operation would have taken around six or seven hours. To put the element of speed into perspective, scanning with the handheld took around three hours including preparation time.

#ARTEC STUDIO MIRROR OBJECTS PRO#

We could have used the tripod-mounted RangeVision PRO 5M scanner for greater accuracy, but for large objects a handheld scanner is a much faster solution, and the Artec Eva easily provides the required surface accuracy of one or two millimeters.

0 kommentar(er)

0 kommentar(er)